About Us

Our experience

Our experience in valve manufacturing has enabled us to become one of the world’s leading suppliers of these products. We pride ourselves on our ability to offer innovative and reliable valve solutions to meet our customers’ needs.

We have developed a deep understanding of production technologies and materials used, and are able to offer high quality products at competitive prices. Because of our attention to detail and our commitment to providing exceptional customer service, we have become a trusted partner for many customers around the world.

Find out who we are

ItalBest Valve has become a well-known and respected valve manufacturer, both in Italy and around the world, thanks to the entrepreneurial and determined spirit of our founder. We are driven by a strong desire to improve and work on new, innovative ideas.

Our production range includes ball valves, subsea ball valves, lubricated plug valves, triple offset butterfly valves, and HIPPS valves. Italbest Valve produces valves for every temperature, up to +650° C and cryogenic, for temperatures as low as -196° C and can offer you a fast-track delivery service for all valves thanks to a large in-house stock.

Given the projected growth of our ball valve production, and the steady increase and addition of the production of plug, butterfly, and HIPPS valves in our product line, our company requires a larger space. ItalBest Valve has purchased a new facility with a total area of 75.000 m2 of workshops and offices in Lonate Ceppino (VA) (North of Italy) making us the largest valve manufacturer, not only in Italy but in all Europe. We also have two ovens for varnishing and coating, sandblasters, and cranes lifting from 10 to 50 tons worth of weight. ItalBest Valve owns over 15 test benches and performs both classic hydraulic/gas tests and non-destructive tests.

We have space to do the special tests like a hyperbaric test and others of different materials and large dimensions that which can be carried out with the help of an 8-meter-deep pit, to test with high-pressure.

Specifically, the tests that can be performed in ItalBest Valve are:

- Magnetic Test

- Hardness Test

- Dye Penetrant Test

- Cryogenic Test

- Hyperbaric Test

- High Temperature Test

- Visual Dimension Test

- Ultrasonic Test

- Fugitive Emission Test

- Positive Material Test and others

Furthermore, we provide customizable design features such as:

- Fully Welded Design

- Cryogenic Applications

- High Temperature Applications

- Stem Extensions

- Pup Pieces

- Transition Pieces with BW (ButtWelded) Ends

- Metal-to-Metal Ball and Seats

- Double Piston Effect

- Self-Relieving Seats

- Stem/Seat Grease Injection

- ENP (Electro Nickel Plating)

- TCC (Tungsten Carbide Coating)

- CCC (Chromium Carbide Coating)

- Manual or Actuated Operation

Our goals

Our joint experience

ItalBest Valve’s experienced and dynamic staff works tirelessly to ensure the best products and service are provided to meet all our clients’ needs. Our expert know-how and state-of-the-art, high-performance production unit, in combination with the latest engineering software and tools, has allowed us to develop customized products that can meet the demands and requirements of our clients.

One of ItalBest Valve’s many strengths is the strict attention to details in every phase of production and in the quality of both the raw material and the finished product. It doesn’t stop there: our after-sales service team is able to provide assistance on-site or remotely to ensure the best value and performance of our valves.

1

Reliability

2

Attention to all requests

3

Precision at every stage of production

4

High-quality finished products

5

After-sales services

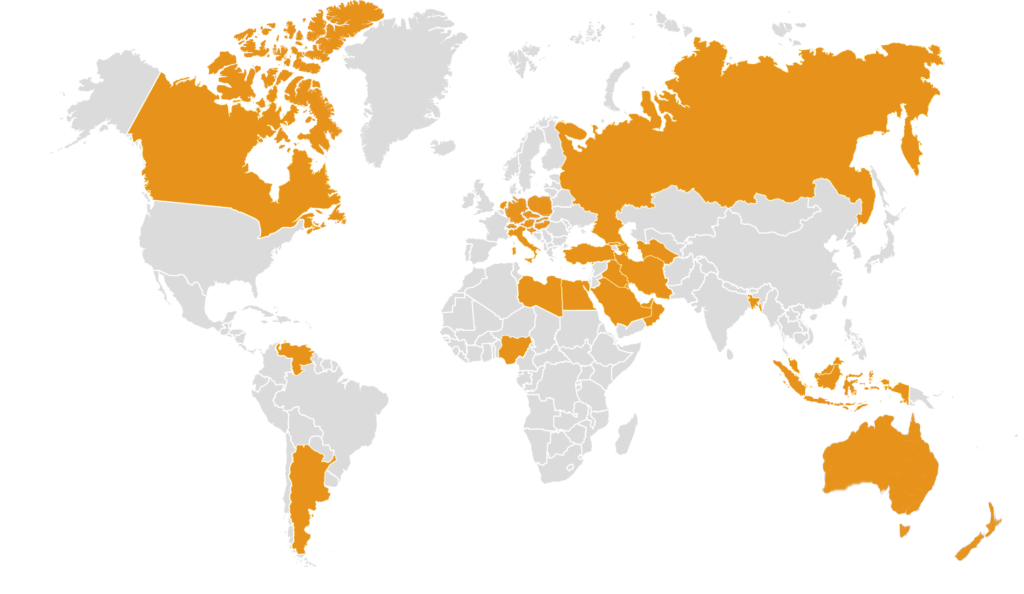

Italbest Valve in the world

ItalBest Valve S.r.l has experienced rapid growth in recent years, developing a foothold in major international markets. We have also become qualified as official suppliers for major multinational construction and energy companies.

ItalBest Valve is constantly looking for new business opportunities and has experienced notable progress in recent years around the world. We are always working hard to expand our market and to develop new and innovative engineering technology and concepts.